Currently Empty: ₹0.00

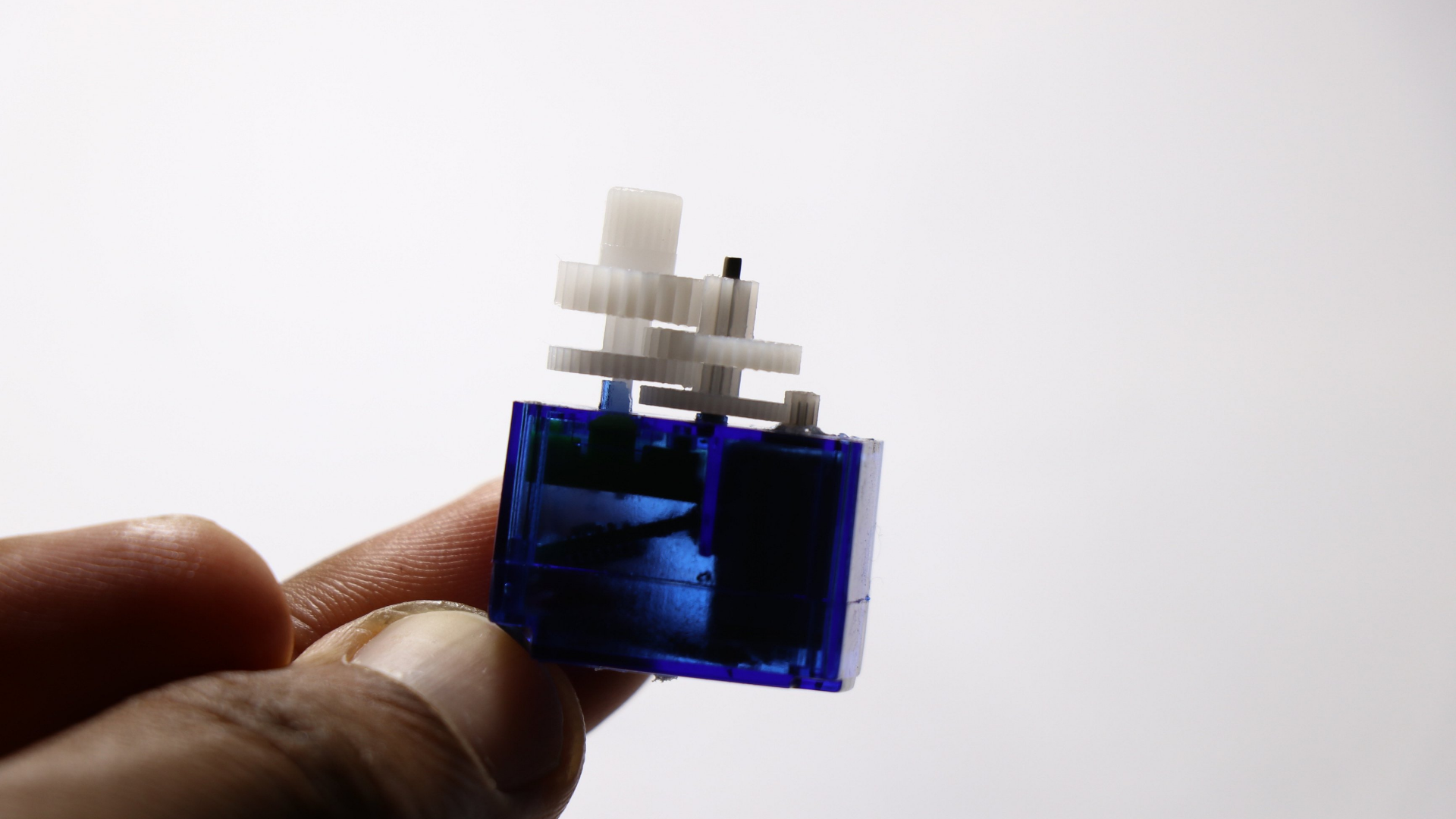

Servo motors precisely control position and speed. The mechanical position of the shaft can now be sensed using a potentiometer. As a result, it is linked to the motor shaft via gears. The potentiometer converts the shaft’s current position into an electrical signal, which is then compared to the command input signal. Electronic encoders or sensors sense the position of the shaft in modern servo motors.

We provide command input based on the position of the shaft. An error signal warns the user if the feedback signal differs from the specified input. We magnify this error signal and feed it into the motor, causing it to revolve When the shaft reaches the required position, the error signal becomes zero, and the motor comes to a halt while holding the position.

Electrical pulses are used as command input. Because the real input to the motor is the difference between the feedback signal (current position) and the necessary signal, the speed of the motor is proportional to the difference. The motor’s power consumption is related to the distance it must travel.

Servomotor command and control:

A servomotor typically turns 90 degrees in either direction, allowing for a maximum movement of 180 degrees. A standard servo motor, on the other hand, cannot rotate any further due to a built-in mechanical stop.

We remove three wires from a servo: the positive, ground, and control wires. The control wire is used to provide a pulse width modulated (PWM) signal to a servo motor. Every 20 milliseconds, a pulse is transmitted. The position of the shaft is determined by the width of the pulses. for instance, A 1ms pulse will move the shaft anticlockwise at -90 degrees, a 1.5ms pulse will move the shaft to the neutral position of 0 degrees, and a 2ms pulse will move the shaft clockwise at +90 degrees

Variable pulse width control servo motor

When we order a servo motor to move by applying an adequate width pulse, the shaft moves to and maintains the required position. The motor, on the other hand, is resistant to alteration. Pulses must be repeated in order for the motor to maintain its position.