Currently Empty: ₹0.00

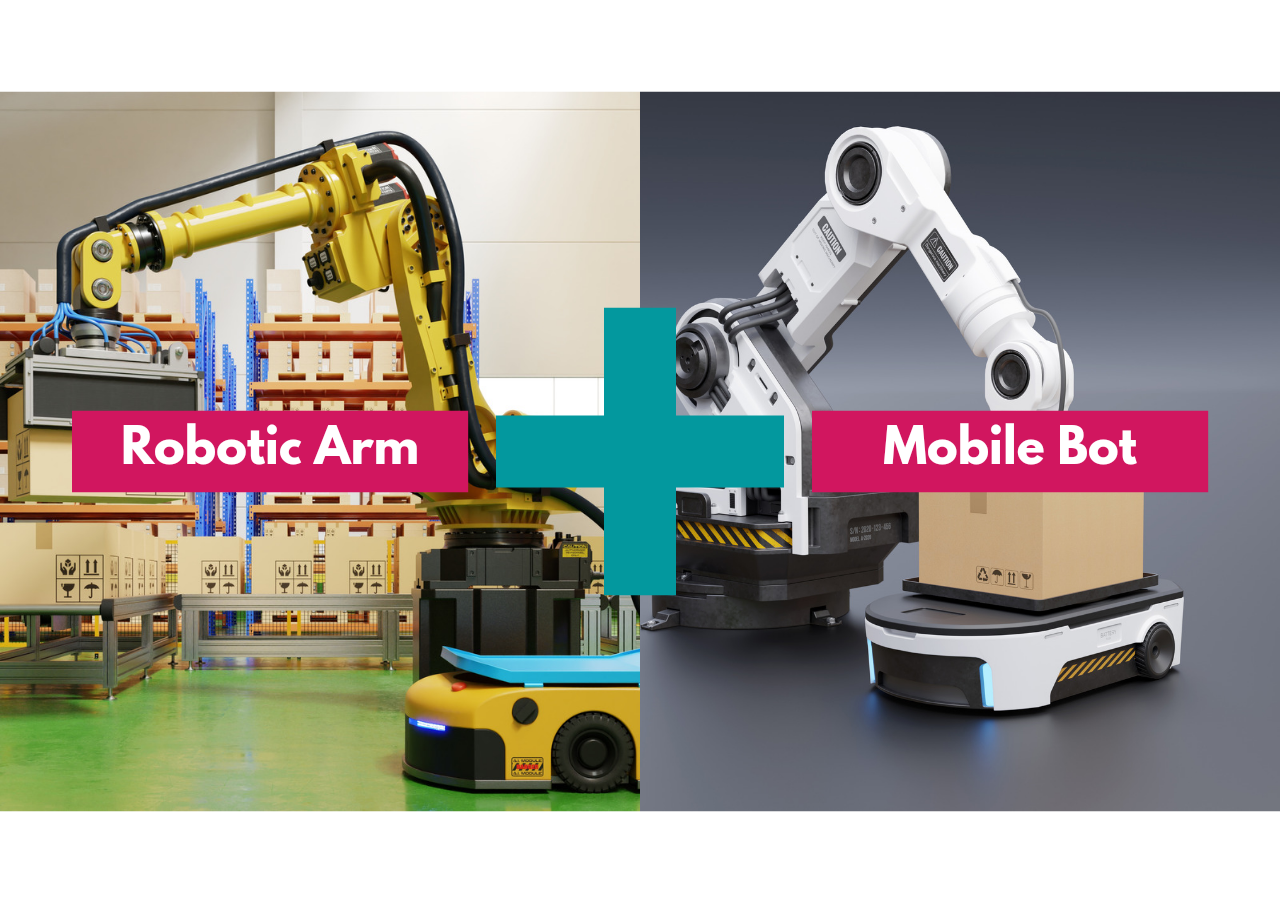

Material handling, welding, assembling, and inspection are all common applications for heavy-duty industrial robots. On the other hand, mobile robots were used to transfer loads from one area to another, even autonomously (Automated Guided Vehicle). Have you ever considered what would happen if the two aforementioned merged and worked together to perform specified tasks? Robotics technology is developing in this direction, to be sure. It has no fixed position and can travel across the entire work surface with greater precision.

Quantec is a sophisticated system that integrates kuka robots, mobile technologies, and other vital components to process even large components.

It is totally an omnidirectional wheel system capable of hauling loads of up to 7 tonnes, with the integrated robot providing a payload capacity of 150 kg. It has a long reach of 3300 mm and a good positioning precision of +/- 5 millimetres.

Robotnik mobile bot and Universal Robots are used to do pick and place activities in large regions. Pick and place, component feeding, metrology, quality control, operations on massive components or packing, cleaning, polishing, screwing, drilling, and other industrial applications are all possible with it.

With a high precision cycle speed of 1.5m/s, 250 kilogramme payloads can be carried. The fact that it can be operated via Bluetooth and Wi-Fi connections adds to its usefulness.

This robot is only available from IAM Robotics for pick and place jobs. Swift, which has a six-axis arm, can retrieve items from both sides of the aisle, from floor-level shelves up to seven feet high, fast and accurately. A robust foundation for the high-speed arm, as well as a conveyor option for automatic tote transfer, is provided by a 20kg weight.